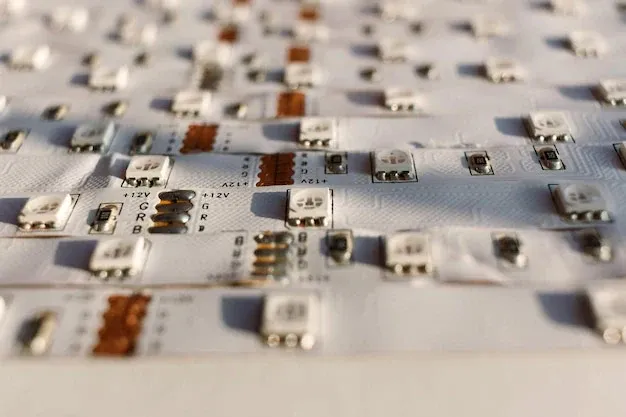

Light Emitting Diode (LED) PCBs

LED is an acronym for light-emitting diode, which is a semiconductor diode. The LED is soldered to the printed circuit board and features a chip that creates the light as electrically connected. A thermal heat sink and a ceramic base are used to bond the chip. Needless to say, LED PCB is the core of LED lighting, and an LED PCB is easy to create a high volume of heat, making it hard to cool with traditional methods.

LED PCB

As we all know that LED will generate more heat compared with other electronic parts, which required the PCB to have a better ability for dissipating heat.

For these special requirements, metal core PCB are frequently used on LED PCB, especially aluminum core PCB.

Now SMD packaging type is the most widely used packaging form in LED applications. In general, it’s limited for the light emitted from a single LED component. So multiple LED components would be used for a single light fixture to achieve sufficient light. Like other semiconductor devices, PCB is the best method to electrically connect the LED components. And a PCB with LED components soldered is usually called as “LED PCB”.

Advantages of LED PCB:HDI PCB:

When it comes to the advantages of using LED PCB, well there are plenty of them and we are now going to mention a few so that you know about the application too.

Light In Weight

No Dimension Issues

Efficient Low Power Consumption

Available In Different Sizes

Heat Dissipation Performance

Dust and Moisture resistant

May be used in silver flex membrane switches and copper flex membrane switches.

The Application of LED PCB:

Telecommunications Industry

LED indicators and displays are always used for telecommunications equipment because of the surrounding machinery, the excellent heat transferability. So aluminum-based LED PCBs are extremely useful in this application.

Consumer Electronics Industry

Consumer electronics are those devices that are being used by humans on a daily basis. These electronics include smartphones and computers, in fact, even the new forms of fridges also have electronic components in them. The best part about the LED PCBs is that they offer low units per cost which make the price of the final product relatively less than what it’s supposed to be.

Medical Industry

Lighting tools used in surgeries and medical examinations commonly use high-powered LED lights, and these LED lights often use aluminum PCBs. This is primarily due to the durability and heat transfer capabilities of aluminum PCB LEDs — this ensures medical equipment is functioning properly regardless of the number of patients cycling through a medical office.

Have Questions?

If you have any questions or need any further information, please feel free to contact your dedicated customer service.